What Should Keep in Mind When Operating the Fabric Bursting Strength Tester

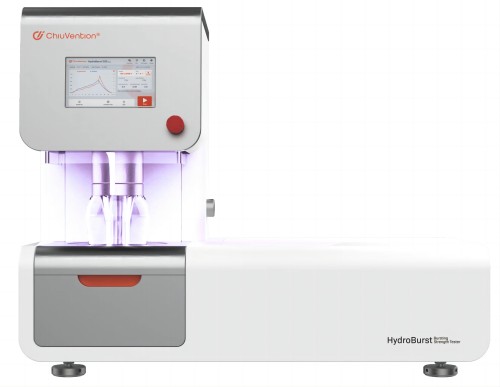

A fabric bursting strength tester is a vital tool for evaluating the durability and performance of textiles under multi-directional pressure. Whether used for quality control, research, or compliance with standards, such as the hydraulic bursting strength test, this instrument ensures textiles meet the required specifications. However, proper operation is crucial to achieving accurate and reliable results. This article outlines key points to consider when operating a bursting strength tester, ensuring efficiency, safety, and compliance with testing standards.

The Basics of Bursting Strength Testing

Bursting strength is the resistance of a fabric to rupture when subjected to a uniformly distributed pressure. The fabric bursting strength tester uses a diaphragm to apply pressure until the material bursts, recording the force required for failure. This test is essential for industries like apparel, home furnishings, and industrial textiles, where material strength is critical.

Pre-Operation Preparations

1. Familiarize Yourself with the Machine

Before starting the bursting strength tester, review the user manual and understand the components, such as:

- The pressure diaphragm applies force to the fabric.

- The clamping mechanism for securing samples.

- The control interface for setting and monitoring pressure levels.

Knowledge of these components helps ensure smooth operation and avoids mistakes.

2. Verify Calibration

Regular calibration of the tester is essential for accurate results. Use certified calibration tools and follow the manufacturer’s guidelines to confirm that the machine meets the required standards. Calibration is particularly important for compliance with methods like the hydraulic bursting strength test.

3. Prepare the Samples

Proper sample preparation is critical for reliable results:

- Cut Samples Correctly: Ensure samples are cut to the specified size and free from defects or wrinkles.

- Condition the Samples: Pre-condition the fabric in a controlled environment, adhering to industry standards like ASTM or ISO.

Key Considerations During Operation

1. Secure the Sample Properly

Place the fabric sample on the diaphragm and secure it tightly using the clamping system. Improper clamping can lead to inaccurate results, as loose samples may shift under pressure.

2. Monitor Pressure Application

- Uniform Pressure: Ensure the pressure is applied uniformly across the sample to mimic real-world stress conditions.

- Incremental Increase: Gradually increase the pressure to prevent sudden bursts that could damage the machine or skew results.

3. Use the Correct Testing Standards

Follow the appropriate testing standard, such as:

- ISO 13938-2: A widely recognized method for textile mullen bursting strength.

- ASTM D3786: Common in North America for fabric testing.

These standards outline procedures, sample dimensions, and acceptable ranges for test results, ensuring consistency.

4. Observe and Record Results

Modern bursting strength testers often include digital displays or software for capturing data. Record the burst strength value as soon as the sample ruptures. For manual machines, note the maximum pressure applied before failure.

Post-Operation Practices

1. Clean the Machine

After testing, clean the diaphragm, clamps, and surrounding area to remove any debris from ruptured samples. Regular cleaning prolongs the machine’s lifespan and maintains accuracy.

2. Inspect for Wear and Tear

Check components like the diaphragm and hydraulic system for signs of wear. Replace any damaged parts promptly to avoid compromising future tests.

3. Store Samples and Data

Preserve tested samples for reference, especially in cases of disputes or quality audits. Store test data systematically, either digitally or in physical records, for traceability.

Safety Considerations

Operating a fabric bursting strength tester involves certain risks. Follow these safety guidelines:

- Wear Protective Gear: Use safety goggles and gloves to protect against sudden ruptures or debris.

- Avoid Overloading: Do not exceed the machine’s maximum pressure rating, as it may cause damage or accidents.

- Power Supply Checks: Ensure a stable power supply, especially for hydraulic bursting strength tests, as voltage fluctuations can affect performance.

Common Mistakes to Avoid

- Inconsistent Sample Preparation: Variations in sample size or conditioning can lead to unreliable results.

- Skipping Calibration: Neglecting regular calibration undermines the tester’s accuracy and reliability.

- Rushing the Test: Applying pressure too quickly may not accurately replicate real-world conditions.

- Improper Clamping: Failure to secure the sample tightly can result in slippage and inconsistent results.

Enhancing Efficiency with Advanced Features

Modern bursting strength testing machines often come with advanced features to improve efficiency:

- Digital Pressure Controls: Allow precise pressure application and real-time monitoring.

- Automated Data Recording: Reduces human error and enhances traceability.

- Multi-Sample Testing Capabilities: Increase throughput in high-volume testing scenarios.

Industry Applications

The fabric bursting strength tester is used in diverse industries, including:

- Apparel Manufacturing: To ensure fabrics can withstand wear and tear during use.

- Home Furnishings: For testing upholstery and curtains that face constant stress.

- Industrial Textiles: For materials like geotextiles and protective clothing, where strength is critical.

Conclusion

Operating a fabric bursting strength tester requires meticulous attention to detail, from sample preparation to post-test cleaning. Adhering to standards like the hydraulic bursting strength test ensures reliable results and compliance with industry benchmarks. By following the guidelines outlined above, operators can maximize the efficiency, accuracy, and longevity of their bursting strength machine, supporting high-quality manufacturing processes and robust material performance.

For more details on textile testing methods and machines, contact us:

Website: https://chiuvention.com/

WhatsApp: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention .com